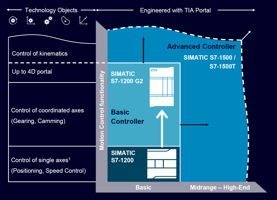

Siemens has revolutionized its automation offering with the new SIMATIC S7-1200 G2 controller,...

Why Your Variable Frequency Drives Might Be Sabotaging Your Power Quality and What to Do About It

Power quality isn't just an electrical engineering buzzword—it's the difference between a smooth-running facility and one plagued by mysterious equipment failures, excessive energy bills, and frustrated maintenance teams. If you've ever wondered why some variable frequency drives(VFDs) seem to create more problems than they solve, the answer often lies in harmonics.

The Hidden Problem with Traditional VFDs

Traditional VFDs are power quality polluters. When these drives convert AC power to control motor speed, they generate harmonic distortion that flows back into your electrical system. These harmonics can cause transformer overheating, neutral conductor overloading, and interference with sensitive equipment. You might notice drives overheating or experience power insufficiencies.

Most traditional VFDs produce total harmonic distortion(THDi) levels of 30% or higher, forcing facilities to install additional equipment like harmonic filters or line reactors—band-aid solutions that add cost and complexity while only partially addressing the root problem.

How Siemens G220 Clean Power Technology Changes the Game

The Siemens SINAMICS G220 with Clean Power technology keeps harmonics below 2%, meeting the stringent IEEE 519 standard that many facilities struggle to achieve. The secret lies in the integrated Active Infeed Unit, which actively conditions the power flowing back to your electrical system.

Think of it as having a built-in power quality filter that works continuously to clean up the electrical signal—a fundamental shift in how drives interact with your facility's electrical infrastructure.

Real-World Impact on Your Operations

Reduced harmonics mean less heat generation in transformers and electrical panels, extending their lifespan and reducing cooling costs. Your neutral conductors won't be overloaded with harmonic currents, eliminating a common source of electrical fires. Most importantly, you'll see reduced overall system energy losses, as clean power flows more efficiently through your distribution system.

The G220 Clean Power delivers the same precise motor control, safety features, and energy efficiency you'd expect from a premium drive, while simultaneously solving the harmonic problem that traditional VFDs create.

Industry Applications and Economics

The marine industry has quickly adopted Clean Power technology for deck machinery and winches, where harmonic standards a restrictly enforced. Food and beverage processors, chemical plants, and manufacturing facilities with multiple drives all benefit from cleaner power that doesn't compromise electrical system integrity. In addition, facilities in industries with evolving power compliance regulations like data centers and those of the medicinal (hospitals and pharmaceuticals) would also benefit from the use of the G220 with Clean Power.

While the initial investment might be higher than a standard G220, the elimination of power quality problems and improved energy efficiency create compelling returns. The G220 Clean Power accomplishes in one integrated solution what traditionally required multiple separate components.

The SINAMICS G220 represents a fundamental shift—drives that act as responsible members of your facility's electrical ecosystem rather than just motor controllers. In an era where every kilowatt-hour matters and electrical reliability is paramount, Clean Power technology isn't just an upgrade; it's essential for facilities that refuse to compromise on power quality.

To learn more about the Siemens SINAMICS G220 contact marketing@eandm.com today!